Bullmer Premium Cut Single Ply Cutter is designed for precision cutting of single layers of fabric in textile and garment manufacturing. Some of its standout features include: High Cutting Precision: The machine offers accurate, clean cuts, even on intricate or complex patterns, making it ideal for industries requiring precise fabric cuts for high-quality products. Fast Cutting Speed: The cutter is designed for high-speed operations, increasing production efficiency without sacrificing cut quality. It can handle a wide range of materials, from delicate fabrics to heavier textiles. Advanced Control System: The cutter often includes a user-friendly, automated control system, which allows operators to input patterns, manage cutting parameters, and optimize cutting paths for efficiency. Single-Ply Cutting Capability: Unlike other machines that cut through multiple layers, the Bullmer cutter is specialized for single-ply cutting, ensuring the highest level of accuracy without distortion that might occur with thicker stacks of fabric. Minimal Fabric Waste: The precise cutting reduces material waste, which is crucial for cost-efficiency and sustainability in fabric-intensive industries. Versatility in Material: It is capable of cutting a wide range of fabric types, including lightweight to medium-weight textiles, leather, and synthetics. Durability and Reliability: Built to handle continuous use in high-volume production environments, the Bullmer cutter is known for its robust construction and long service life. Low Maintenance: The cutter is designed for minimal upkeep with easy access to critical components, reducing downtime and ensuring smooth operations. Ergonomic Design: Many of these models feature an ergonomic design to reduce operator fatigue, making them more comfortable for long periods of use. Safety Features: Safety mechanisms such as automatic shutoffs, protective covers, and sensors are integrated to ensure safe operation for the user. These features combine to make the Bullmer Premium Cut Single Ply Cutter a valuable tool for businesses aiming for high precision, speed, and efficiency in textile cutting.

The Premiumcut is a versatile cutting system designed for a wide range of materials, including prepreg, carbon, glass, Kevlar, foams, and honeycombs. It features interchangeable tools such as drag knives, reciprocating knives, rotary knives, and ultrasonic knives, ensuring flexibility for various cutting needs. The powerful vacuum holds the material in place while the conveyor automatically advances it, enabling efficient, nestable cutting for minimal material waste and maximum productivity. For fixed-sheet cutting, a static bed option is available. Ply identification is facilitated through various methods, including a pen, inkjet marker, laser-guided pickup, or fully automated robotic ply handling for streamlined operations.

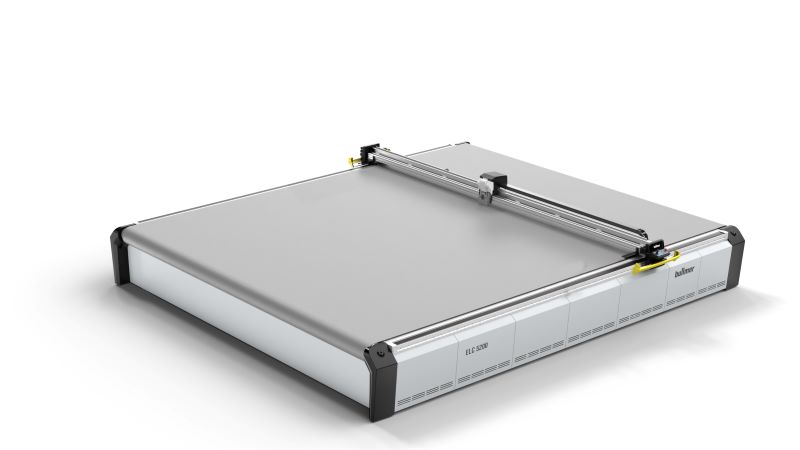

Single-Layer Cutter: Bullmer PREMIUMCUT 1620 CV with AWM 2000

AWM 2000 Unwinding Tool Features:

- External motor for material roll (without reverse wound option).

- Synchronized with the cutter.

- Electric edge control system for precision alignment.

- Pneumatic cradle for easy loading and unloading.

- Roller system for leveling and tension compensation.

- Material end sensor for automatic operation.

- Airbag support during cutting to prevent stress and wrinkling.

- Working width: 1,600 mm.

- Max. material roll weight: 100 kg.

- Max. material roll diameter: 500 mm.

- Voltage: 230/400V, 50/60Hz, 3-phase, N, PE.

PREMIUMCUT 1620 CV Cutter:

- Cutting window:

- Width: 1,600 mm

- Length: 2,000 mm

- Cutting thickness: 880 ± 40 mm

- Max cutting speed: 120 m/min.

- Max acceleration: 2 g.

- Compressed air consumption: 6 bar, 200 l/min.

- Network port included.

- Software included:

- Cutting report and time management.

- Optimization of cutting sequence.

- Cutting path simulation with laser pointer.

- QualiCut for identifying inside and outside corners.

- Voltage: 400 V, 50/60 Hz, 3-phase, N, PE.| 220 3 PHASE , 440 V OPOTIONAL

Design and Appearance:

- Color: RAL 7016 (Anthracite gray) for the cutter, RAL 9002 for other parts.

Operator Panel:

- Standalone version, for operation in a standing position.

Vacuum Device:

- Power: 7.5 kW.

- Features: Soundproof housing, frequency-controlled, exhaust air silencer.

Material Feeding & Reception Extensions:

- Feeding Zone Extension:

- Working width: 1,600 mm.

- Extension length: 800 mm.

- Reception Area Extension:

- Working width: 1,600 mm.

- Extension length: 2,000 mm.

Cutting and Support Tools:

- Cutting Mat: 4 mm gray mat.

- Working width: 1,600 mm.

- Working length: 2,000 mm.

- Tool Module for Up to 3 Tools: Includes additional connections for cut height adjustment and laser pointer.

- Electric Rotary Wheel Cutter: Includes Ø 32 mm adapter.

- Marker and Pen Modules: For marking or pen-based writing.

- Hole Punch: For holes 1-10 mm, with suction for drill waste.

- Lay-On Roller: Ø 80 mm, for material guidance on the cutting surface.

Additional Features:

- Mat Cleaning Tool: Brush-based cleaning tool for the cutting mat.

- Off-Load Support with Monitor: Visualizes cutouts and part descriptions on the receiving table.

- Includes hardware and software for cut-file information display.

PLEASE NOTE THAT NOT ALL OF THESE FEATURES ARE STANARD BUT OPTIONAL CALL FOR IMFORMATION

About Premiumcut Composites

The Premiumcut is a versatile cutting system, equipped with a wide range of interchangeable tools, allowing you to cut a variety of materials. The slogan “Invest once, cut everything” reflects the system’s flexibility. The available tools include:

- Drag knife

- Electric or pneumatic reciprocating knife

- Driven rotary knife

- Ultrasonic knife

- Pen or inkjet marker

The material is securely held in place against the cutting bed by a powerful vacuum system, while the conveyor automatically advances the material for efficient processing.

The Premiumcut is capable of cutting a broad range of materials, such as:

- Prepreg

- Dry carbon

- Glass

- Kevlar

- Tooling consumables

- Foams

- Honeycombs

The system utilizes a conveyor to support unlimited nesting of components, which helps minimize material waste and maximize productivity. For companies that cut from fixed sheets of material, a static bed option is also available.

For ply identification, the Premiumcut offers several options, including:

- Standard pen or labeling system

- Inkjet part marker

- Offloading screen to guide the operator

- Laser-guided pickup for precise handling

Additionally, ply pickup can be fully automated with a robotic system, which picks the plies in the required order and stacks them automatically, eliminating the need for manual handling.

CLick here for quick video