Bullmer High-Ply Fabric Cutting Machine: Precision, Efficiency, and Durability

The Bullmer High-Ply Fabric Cutting Machine stands as a leader in the industry, delivering unparalleled cutting precision and exceptional durability. Engineered for high-output mass production across multiple industries, the Bullmer ProCut is the ultimate solution for businesses demanding both quality and efficiency in their cutting operations.

Key Technology Features:

Knife Intelligence Technology

- Unmatched Precision: The advanced knife drive system is equipped with a sensor that continuously monitors and adjusts the knife angle in real-time, correcting any deviation. This ensures consistent cutting accuracy, even on the most intricate materials.

Double Knife Plate Technology

- Enhanced Cutting Quality: The cutting head features two knife plates—a large one that applies pressure to the fabric, and a smaller one that doesn’t contact the material. This unique design prevents misplacement of cut pieces, resulting in higher cutting quality and fewer material defects.

Auto Cleaning Device

- Automatic Efficiency: Unlike other machines that require manual cleaning, the Bullmer ProCut features an auto cleaning system. The cutter automatically clears scrap material from bristle bricks, reducing downtime and eliminating the need for one extra day of manual labor.

Auto Lubrication System (Patent Technology)

- Extended Machine Life: The Bullmer ProCut comes equipped with an automatic lubrication system, patented for its effectiveness in reducing wear and tear, thereby significantly extending the lifetime of the cutting machine.

Precision Engineering for Durability

- Alloy Casting Cutting Head: The cutting head is made with high-precision alloy casting, ensuring long-term durability and consistent performance under heavy-duty conditions.

- Rust-Free and Stable Base: The aluminum profile base is designed to never rust, providing unmatched stability and extending the machine's lifespan.

Enclosed Linear Modules (X1Y Axis)

- Dust Proof & Low Maintenance: The cutting machine uses enclosed linear modules for the X1Y axis, offering dust-proof protection and maintenance-free operation. This ensures a smooth, reliable cutting experience with minimal downtime.

User-Friendly Design

- Drawer-Style Electric Control Box: The Bullmer ProCut features a drawer design for the electric control box, making maintenance and access incredibly convenient, saving both time and effort.

Target Markets:

- Automotive

- Apparel

- Upholstery

- Aircraft

- Analog Industries

The Bullmer ProCut is ideal for industries requiring high-precision cutting of a variety of materials and high volumes.

Material Compatibility:

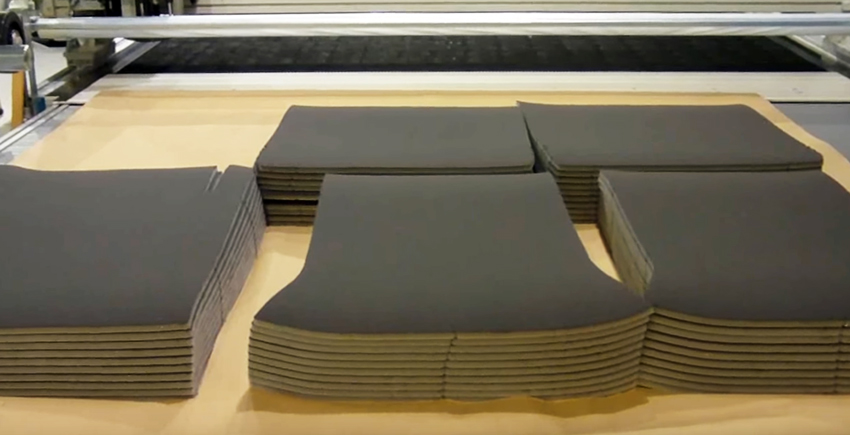

The Bullmer ProCut excels in cutting woven, non-woven, coated, and quilted materials. With its versatile capabilities, it is perfectly suited to meet the diverse needs of modern manufacturing.

Performance Advantages:

Heavy Duty & Configurable

- Unmatched Cutting Capacity: The Bullmer ProCut can be configured with conveyorized cutting windows up to 10 meters, providing exceptional efficiency and productivity for large-scale operations.

- Versatility in Cutting Height: Versions are available for a maximum cut height of 50mm or 80mm, both powered by a vertical oscillating knife to handle various fabric thicknesses and materials.

Ideal for High-Volume Production

- Designed for mass production, the Bullmer ProCut is the cutting-edge solution for industries demanding high-output production without compromising on quality.

Why Choose Bullmer ProCut?

- Precision Cutting: Ensures high-quality cuts with minimal material waste.

- Low Maintenance: Features like auto-cleaning, auto-lubrication, and dust-proof guides reduce downtime.

- Durability: Robust design ensures a long machine life even under the most demanding production conditions.

- Efficiency & Productivity: Ideal for industries with high-volume cutting requirements, delivering fast turnaround times and unrivaled efficiency.

Bullmer ProCut: The strongest, most precise cutting machine on the market—designed for industries that demand perfection at every stage of the cutting process..

Click here to schedule a demo or get free time study

Dematron Automation Specializes in Cutting Room Optimization and offers some of the best solutions to minimize labor cost and increase production. With the quickest return on investment and longest equipment longevity Dema is the right choice! For a free consultation call 1-888-492-5553