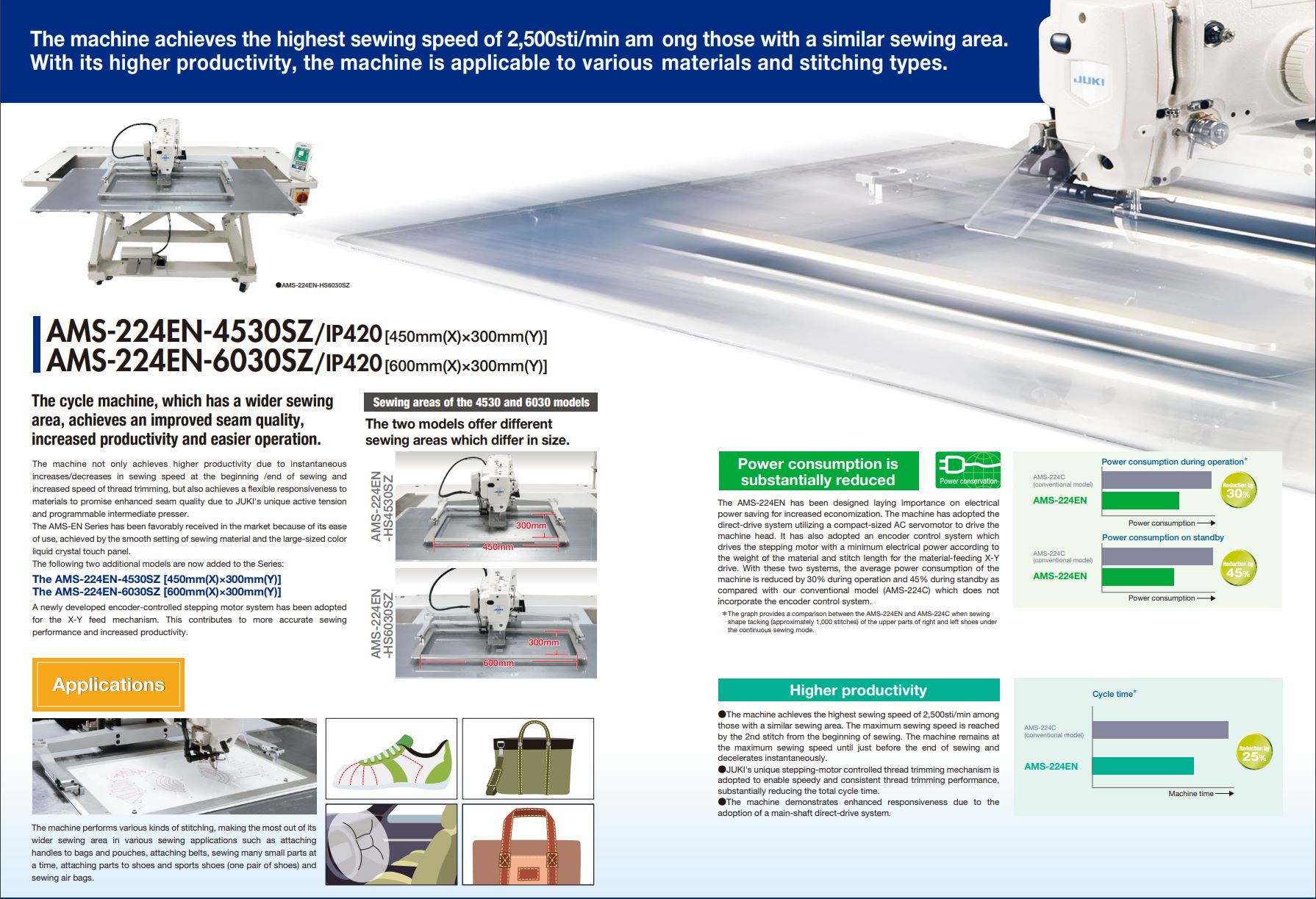

The AMS-224EN-4530 are computer-controlled cycle machines with an input function. They have a wider sewing area and achieve the highest sewing speed of 2,500 stitches per minute among machines with a similar sewing area. These machines are designed for various sewing applications such as attaching handles to bags and pouches, attaching belts, sewing multiple small parts at a time, attaching parts to shoes, and sewing airbags.

The AMS-224EN series machines have improved seam quality, increased productivity, and easier operation. They achieve higher productivity through instantaneous increases and decreases in sewing speed at the beginning and end of sewing, as well as increased speed of thread trimming. The machines also have flexible responsiveness to materials, thanks to JUKI's unique active tension and programmable intermediate presser.

One of the key features of the AMS-224EN machines is their power-saving design. They incorporate a direct-drive system that utilizes a compact-sized AC servomotor, reducing power consumption by 30% during operation and 45% during standby compared to the previous model (AMS-224C). The machines also feature an encoder control system that drives the stepping motor with minimum electrical power based on the weight of the material and stitch length.

In terms of productivity, the AMS-224EN machines achieve the highest sewing speed of 2,500 stitches per minute. They maintain this maximum speed until just before the end of sewing and decelerate instantaneously. The machines also have a stepping-motor controlled thread trimming mechanism for speedy and consistent thread trimming performance, reducing the total cycle time.

The AMS-224EN machines offer enhanced sewing quality with an encoder-controlled X-Y drive stepping motor that improves feed accuracy. This reduces the deformation of sewing patterns that can occur at high speeds or when sewing heavy-weight materials.

These machines also feature a semi-dry head, where the frame is lubricated with grease and the hook is fed with a small amount of oil from the oil tank. This prevents products from being stained with oil.

The AMS-224EN machines are equipped with JUKI's active tension technology, which allows for pinpoint changes in needle thread tension during sewing. The needle thread tension can be set based on the material thickness and corrected stitch-by-stitch through the operation panel, resulting in reproducible tension and reduced setup time.

The machines come with a large-sized liquid crystal touch panel, the IP-420, which offers ease of operation and efficient editing work. It displays sewing data such as stitch shape, needle thread tension, enlargement/reduction ratio, sewing speed, and the number of stitches.

Other features of the AMS-224EN machines include a key-lock customization function, simplified operation mode for ease of use, enhanced memory storage capacity for sewing data, and a programmable intermediate presser that allows for height adjustment according to material thickness to prevent stitch skipping and thread breakage.

Overall, the AMS-224EN-4530 machines provide improved productivity, sewing quality, and ease of operation, making them suitable for a wide range of sewing applications.