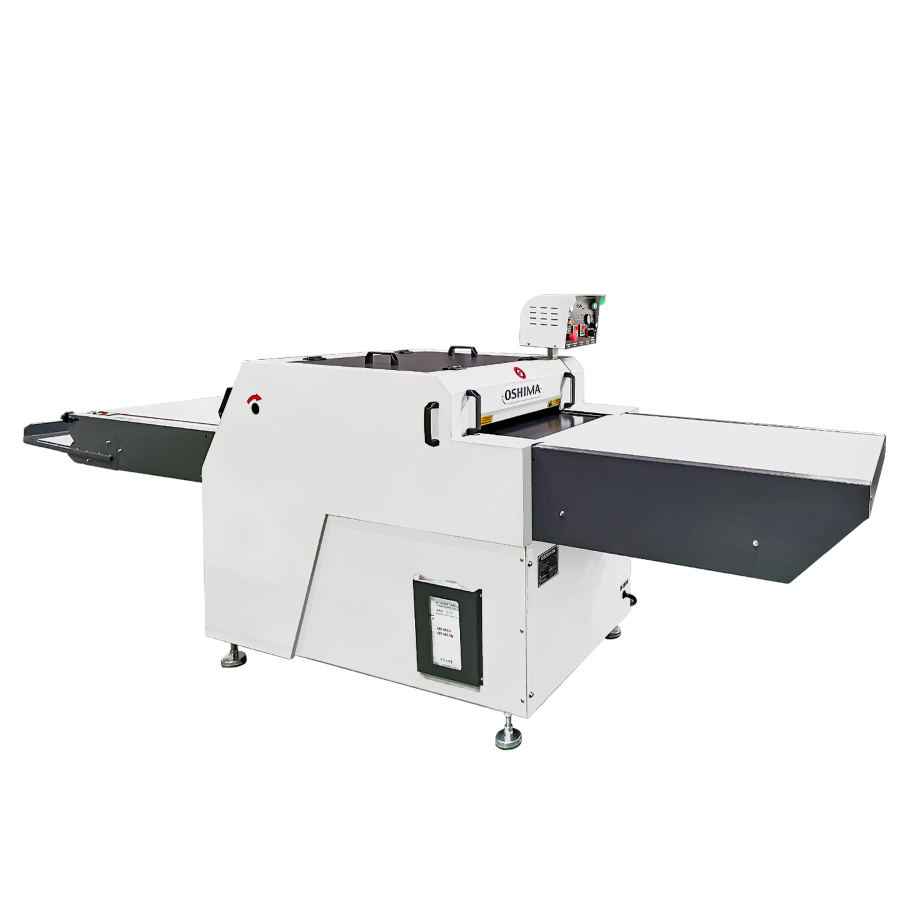

Product Description

Introducing the latest generation of high-performance continuous fusing machines, designed for users who demand precision and reliability.

With a belt width of 60 cm, these machines deliver powerful pressure up to 6 kg/cm² and feature electronic temperature control, adjustable up to 200°C, ensuring a smooth, durable, and flawless bond between fabric and interfacing. The machine is also capable of laminating materials.

A cutting-edge cooling system quickly stabilizes the fused elements, preventing deformation, while synchronized mechanical scrapers and strategically directed compressed air effectively prevent interlining from sticking to the belts.

Key Specifications:

- Air Pressure System: Ensures consistent pressure distribution on the drum for excellent fabric adhesion.

- Two-Stage Heating System: Computer-controlled for precise temperature regulation.

- Advanced Monitoring: Tracks heat generation, belt correction, and pressure adjustments.

- Quick Cooling: Efficient cooling system for fast stabilization and shaping after bonding.

- Moveable Wheels: Equipped with wheels for easy transport and mobility.

- Ideal for Shirt Manufacturers: Perfect for small to medium-sized businesses, especially for collar and sleeve fusing.

- Heater Power: 9.1 kW

- Voltage: 400 V

- Fusing Time: 5-34 seconds

- Compressed Air Required

Product Features

- Brand: Oshima

- Belt Width: 60 cm

- Heater Power: 9.1 kW

- Max Pressure: 6 kg/cm²

- Power Supply: 400 V

- Weight: 370 kg

This machine is perfect for high-demand operations, delivering consistent, top-quality results with every use.