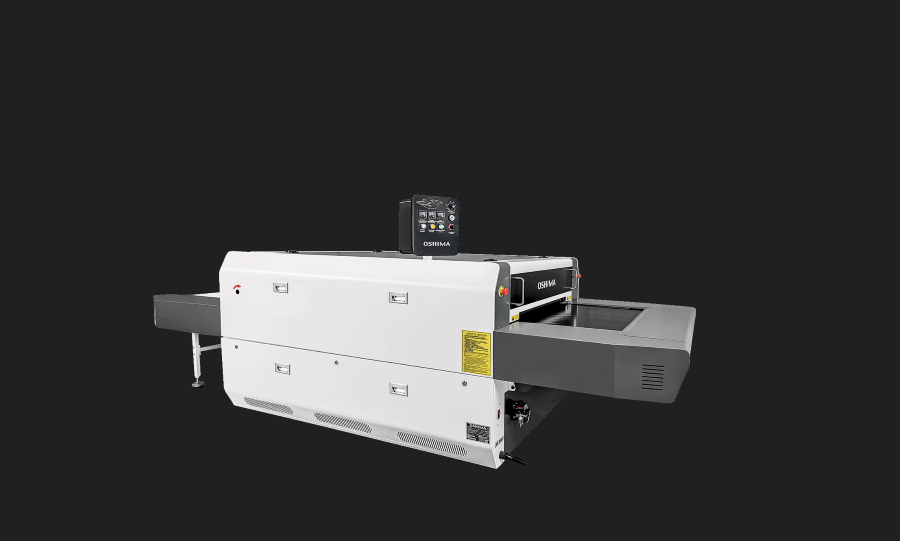

This machine integrates cutting-edge technology with practical features, enhancing operational efficiency while ensuring careful handling of fabrics during the fusing process. If you have further questions or need additional information, just let me know!

APPLICATION

* For the woven/ knitted fabrics fusing.

* Fusing for the whole roll of fabric and interline. The machine can work together with feeding conveyor and collecting stacker as an option.

- High-performance pneumatic cylinder system, 3 times stronger than standard models, ensuring even pressure distribution (maximum 5kg)

- Larger preheating zone, up to 3 times bigger than average, to protect delicate fabrics

- 9-zone PID temperature control system for precise heating

- Automatic cooling-shutdown mechanism for energy efficiency when idle

- Dual-scraper (upper and lower) design for clean removal of fused laminates

- Autonomous shutdown feature to prevent overheating

- Equipped with casters for easy relocation, adapting to changing production needs

If you need information on any Oshima fusing machine product call 1-888-492-5553 USA

Ideal Choice for Knitted Fabrics - Continuous Fusing Machines

Introduction to Continuous Fusing Machines

- Purpose:

Designed for soft and elastomeric knitted fabrics, ensuring high-quality lamination with minimal shrinkage. - Key Feature:

Fitted with PTFE-coated conveyor belts for smooth, efficient, and consistent fusing.

Shrinkage Prevention with the N Series

- Problem Addressed:

Prevents shrinkage issues commonly faced when fusing soft, elastomeric fabrics. - Solution:

The N Series of Continuous Fusing Machines have been specifically engineered to avoid these issues, ensuring a flawless finish every time.

Consistent Pressure Application

- Maximum Pressure:

Up to 10KG to ensure optimal fusing quality. - Pneumatic Cylinder System:

Even pressure distribution across the fabric, preventing wrinkles or uneven bonding.

Automatic Fault Detection

- Self-Diagnosing Technology:

The machine is equipped with automatic fault detection to identify and address issues promptly. - Ease of Repair:

Facilitates quick and easy maintenance, minimizing downtime and improving production efficiency.

Advanced Heating System

- Three-Zone Heating:

Ensures precise and uniform temperature control across the fabric for consistent results. - Automatic Temperature Control:

Adjusts the heat settings for optimal fusing and lamination. - Cooling-Shutdown Feature:

Automatically activates a cooling-shutdown function when not in use, conserving energy and preventing overheating.

Conveyor Belt Technology

- Automatic Conveyor Belt Tracking:

Maintains precise alignment of the conveyor belt, reducing wear and tear and ensuring consistent performance. - Dual-Scraper Design:

Upper and lower scrapers efficiently remove fused laminates from the conveyor belt, ensuring clean surfaces and preventing residue buildup.

Enhanced Mobility & Flexibility

- Movable Rollers:

The machine is equipped with movable rollers for easy transportation and setup, making it adaptable to different work environments.

Conclusion

- Ideal for:

Manufacturers and textile businesses working with delicate, soft, and elastomeric fabrics who need a reliable, efficient, and energy-saving solution for continuous fusing. - Why Choose Us?

High-quality results, consistent performance, easy maintenance, and innovative features make our Continuous Fusing Machines the ideal choice for your fabric production needs.

Contact Us info:dematron.com

- Get in Touch:

For more information or to schedule a demo, contact our sales team today.

This presentation outlines the key features and benefits of the Continuous Fusing Machines designed specifically for soft and elastomeric knitted fabrics. Let me know if you would like to adjust or expand on any section!